LEGENDS REBORN

Long-closed distilleries

brought to life by a marriage of fine aged

single malts, celebrating the golden

era of Scotch Whisky

The Scotland-based Lost Distillery

Company believes it is a tragedy that over one hundred Scotch Whisky

distilleries have been permanently closed during the last century. Despite

being renowned for their excellent quality malts, these distilleries were

largely closed through the effects of war, prohibition, politics and the rise

of mass production. In many instances, if the whiskies made by these distilleries even exist, they are absolutely out of reach even for sampling purposes.

They have successfully set about a unique mission—recreating whiskies from Scotch whisky distilleries that were shuttered long ago. Fortunately, Scotland has detailed records that go back many hundreds of years.

Launched in 2011, the company set out with a straightforward mission of becoming independent Scotch whisky bottlers. In their search for a relevant name for the business they came across many distilleries that were closed and forgotten, hit upon this concept and selected their name. CEO Brian Woods and co-founder Scott Watson consulted with University of Glasgow professor Michael Moss, a renowned historian and archivist, about the possibility of recreating Scotch whisky recipes from long-gone distilleries. They learned that, through research, they could produce a whisky that would represent what a distillery would be making today if it were still around.

Archivist & Blending: Only once they find a lost distillery which made a quality malt of good reputation do they start the

archivist process. They usually create three progressive versions: Classic at 40-43% ABV from 8-12 year old whiskies, Archivist at 46% ABV from 15-18 YO whiskies and Vintage at 46% ABV from 25 YO and older bottles. Prices range in the $40-45 mark for the Classic, $125-150 mark for the Archivist to $ 225-750 for the Vintage versions. Apart from the Classics, the higher range bottlings are un-chillfiltered and display their natural colour.

Their head archivist spends months tirelessly researching each distillery. Reading through hundreds

of historic documents, tax records and photographs to then scientifically guide

a profile of how they believe each whisky would have tasted. Every aspect of

distillery life is researched, from water source to still shape, cask type and

everything in between. Their whisky making team then use this data to bring the

flavour profile to life.

They require ten critical components: the date of last distillation, the region within which the distillery was located, the distillery's water source, the distillery's barley source, the distillery's yeast source, the distillery's drying process, the distillery's mash tun, the distillery's wash back, the distillery's still and the type of wood that was used to mature the whisky. Once these components are determined, Moss and his team of archivists and whisky makers marry together single malt whiskies from distilleries across Scotland in order to create a present day interpretation of that long lost whisky legend.

The Scotch: Blended Malts

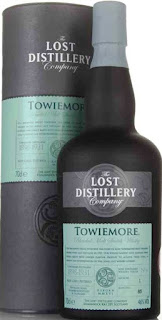

In 2016, Lost Distillery launched three blended malts on the U.S. market as part of its Classic Selection range: Lossit, Benachie and Towiemore, all at 43% ABV and retailing at $43 a 750-ml. Lossit (1817-1967) was once Islay’s biggest producer. Benachie (1824-1913), also known as Jericho, distilled whisky in the Aberdeenshire Hills. Towiemore (1898-1931) was situated just outside Dufftown in Speyside. Differing ABVs will also be offered, with varied pricing.

Lost Distillery’s Classic Selection range also includes three other labels: Stratheden (1829-1926) which was located in Fife; Auchnagie (1821-1911) which was near Pitlochry; and Gerston, situated in Caithness, which had two incarnations (1796-1882 and 1886-1914).

In addition to the Classic Range, Lost Distillery offers two higher tiers. The Archivist Collection includes Gerston, Stratheden Benachie and Auchnagie (all $63). The Vintage Collection, encompasses Gerston, Stratheden and Auchnagie (all $275). Those two upper tiers are distinguished by the older whiskies used in the vattings—typically a 15- to 18-year-old average in the Archivist and 25 years or more in the Vintage—though some younger whiskies are used in these ranges to achieve the flavour profile sought. All the labels from the upper tiers except Benachie are available in the U.S.

Lost Distillery is targeting the cash rich U.S. market, brokered through Miami-based Park Street. The company released another label, Dalaruan, in France end 2016 and is rolling it out more widely today.

TOWIEMORE DISTILLERY

Owned and supported by

renowned whisky entrepreneur Peter Dawson, Towiemore was a victim of bad luck

and ill circumstance. Such troubles would have seemed distant when Towiemore

opened in 1897. Built by local contractor W. Cruickshank on the designs of the

architect John Alcock, both based in the town of Keith, Towiemore was instigated

and bankrolled by Peter Dawson, the distiller, blender, international

businessman and public relations pioneer. The location chosen by this native of

Banffshire is indicative of the attributes required for a late Victorian

distillery to succeed.

The Early Days

Towiemore used water from

the Towie Burn, a source claimed exclusively for the distillery, which flows

through a scenic cleft of woodland originating from the Hills of Towie. A dam

was built within this woodland to control the flow of water to the distillery,

but this was destroyed in 2005 to ensure salmon could travel up-stream.

Towiemore utilised a

two-storey attic malting floor to malt its barley before it was dried on a

perforated floor above a large kiln, with provision to ‘manufacture’ 3,000

bushels of barley per week. The kiln was fired by a mixture of peat and coke,

brought in from Tomintoul and further afield via the rail network.

The peat would be burnt first for a short time so as not to impinge too much of its smoky flavour upon

the malt, whereupon flavourless coke was heaped on top of the peat to finish the process.

Vital Ingredients

Towiemore’s malting

process was supported by the addition of twin ventilated pagoda chimneys,

probably in 1908, as pioneered by Charles C. Doig. Doig’s ventilators

encouraged the kiln’s hot air to spread upwards, resulting in a more efficient

malting process. The malting floor at Towiemore was effective enough to warrant

usage by Distillers Company Limited after the closure of Towiemore’s

distillation plant before it was eventually shut down in 1964.

Mashing first took place

at Towiemore in November 1898. Grist (dried malt barley ground in a Malt Mill)

would be mashed slowly with fresh water from the Towie Burn to create a highly

saccharine wort, rich in maltose ready to react with yeast in the large

washbacks. Towiemore would have used a large wooden mash-tun with a revolving

arm for stirring the mash as sugar was extracted from the malt.

The Equipment

Vienna Yeast, a more

reliable product that could be compressed for ease of transportation had proved

a popular import from the European continent. DCL saw the potential profit in

regulating yeast production to improve the efficiency of the largescale

distillation process. They therefore invested heavily in improving the quality

of British yeast. This process began by funding the experiments of Dr W.

Squires, who offered DCL his own patent version of Vienna Yeast in 1881.

Squire’s process utilised the well-known chemical properties of dense mashes to

produce a better result than standard Vienna Yeast. Vienna Yeast manipulated

the mashing process through higher temperatures and thicker mashes.

Towiemore utilised two

copper pot stills, a wash still and then a pot still, to distil its wash into

spirit in the traditional batch distillation method. Coal fires heated the

underneath of both stills, while a rotating scour prevented burning on the

inside of the still.

Towiemore’s wash still had

a capacity of 17,000 litres while the spirit still could contain 16,000 litres.

Both were of medium build, with slightly long necks and a gently ascending lyne

arm. The ascension of the lyne arm caused more reflux, resulting in a lighter

spirit resplendent with nutty flavours.

Disaster Strikes

Although it produced

excellent, light and sweet Highland style whisky popular both as a pure malt

and for blending, Towiemore’s opening coincided almost exactly to the point the

industry was swept into disaster, entering a malaise that was not to cease

until long after its closure. The amalgamation process may have saved the

whisky industry, but it was not enough to save the unlucky Towiemore, its brand

cast into the annals of whisky history.

Until a lustrum ago.

In 2016, The Lost Distillery Company launched Towiemore as a blended malt, using historical information regarding the distillery to closely replicate Towiemore’s lost whisky.

The blend is presumably based on Towiemore’s revered whisky prior to WWI – the distillery was beset with water issues following the war, most likely due to nearby lime works washing into the Towie Burn, that meant its whisky became cloudy when diluted. The first modern blended malt has been matured in an ex-Sherry cask, and is available as part of The Lost Distillery Company’s Classic Selection at ~US$40, a great value for money proposition. This version of Towiemore blended malt is one Scotch whiskies that could be recommended to bourbon drinkers. Bottled at 43%, its looks are suggestive of that very point. There isn’t any information on whether colouring was added, but, regardless, in the glass it has a light amber appearance, like brushed and faded copper.

The nose is fruity and grassy in almost equal measures, presenting a crisp scent of peaches and straw, like opening a crate of fruit in olden times when they might have packed in some straw for the padding. Mixed in there is just a waft of almonds and vanilla.

Taking a sip, the whisky has a creamy feel that leads one to a peach cream flavour, with a dash of salt. It would be suggestive of a concoction that might go into a ice cream making machine, were it not for the light note of oily creosote nestled into the middle, creating a nice little contrast. The finish extends out of that creosote aspect, running mild, a little dry, and a little spicy.

This version of Towiemore Blended Malt is made up of 15 to 18 year old blended malts.

|

|

|

MATURED IN BOURBON CASKS AND FINISHED IN

Madeira Cask 46% ABV Sherry Cask 43% ABV Port Cask 46% ABV

AUCHNAGIE DISTILLERY

Auchnagie Distillery (or Tullymet as it was later known) was located near the hamlet of Tulliemet, approximately 6 miles South East of Pitlochry in Perthshire. The land in this area is rural, a mixture of pasture and rolling hills, with ample supply of water flowing off of the high ground.

Auchnagie’s channelled water source drained into a specially constructed pool, with a sluice gate positioned at the bottom to control the flow. This construction helped to prolong the distillation season. Barnard noted that there was no production when he visited as it was too warm for mashing – this was considered the norm, as Auchnagie, like other water-wheel powered distilleries was entirely at the mercy of rainfall for power supply.

Successive owners improved Auchnagie’s capacity, not by adding bigger stills but more likely they developed techniques to lengthen the season, such as adding the water pool, or providing consistent supply of barley.

|

|

|

Classic Archivist Vintage

STRATHEDEN DISTILLERY

Alexander Bonthrone

(1798-1890) established the distillery in 1829, when he was 31 years old and

worked the stills for the next six decades, almost until his death in 1890 –

making him one of Scotland’s oldest distillers. He held several civic titles: a

Baillie to burgh magistrate, Justice of the Peace and Municipal Councillor. A

committed Liberal, he advised Herbert Asquith, the local MP on whisky matters.

Asquith later became Prime Minister 1908 – 1916 and stood against Lloyd

George’s proposal of Prohibition in Britain.

Alexander’s younger brother, John Bonthrone (1799-1881), was described as “pioneer of the malt trade” one of Scotland’s first commercial maltsters. He was instrumental in the construction of Fife & Kinross Railway, with the station opening at Auchtermuchty in 1857.

The Early Days

Set in the centre of Auchtermuchty and surrounded by the Lomond Hills, a

well-known habitat of smugglers and illegal distillers – local characters include Lady Miller who kept an illicit still in the hills. The distillery was unusually built in the centre of town and pre-dates courtyard-style distilleries.

Construction was arduous, the water source, a tributary of the river Eden, channelled from the “Lovers pool” by an aqueduct. The water was extremely soft, with a distinct earthy and salty edge to it.

Vital Ingredients

Bere barley was the preferred strain of barley. This “six-row barley” was relatively low-yielding, and produced grain of inconsistent size and a challenge to achieve consistency. Bere barley was favoured until the late 1940’s, when two-row barley became available. This modern strain produced a more full-bodied, maltier style of barley, with higher yields and better tolerance to Scotland’s climate.

Yeast cultures were harvested from the residue of washbacks after fermentation, often prone to contamination. Commercial yeast only became available from the 1870’s, with the Distillers Company Limited (DCL) building a yeast house at Cameronbridge Distillery.

Peat was brought from Orkney as a reciprocal trade of John Bonthrone’s malting business – Orkney peat preferred to local peat had a pronounced briny note and would provide a more coastal style of spirit rather than a typical lowlander.

The Equipment

The mash tun is recorded as being a copper vessel of 2000 gallons capacity for heating water, and a wooden tun 11 feet in diameter and 4 1⁄2 feet deep. The stills were unusually small, the wash still and spirit still were 960 and 460 gallons respectively. The latter still purchased from a smuggler 60 years prior, and original still installed in 1829. Alexander Bonthrone would not exchange his old stills for fifty newer versions twice the capacity, and he attributed the quality of the whisky to the water, and the small, old stills.

Whisky distilled in early 19th century was generally not aged. Duty in Lowland distilleries was paid on proof gallons produced – there was no incentive to let it mature. In 1887 five merchants took everything the distillery could produce – clearly the distinctive spirit produced at Stratheden was high quality. Casks used were sherry – bonded warehouse records illustrated in December 1924, 475 hogsheads & 131 butts. This inventory was drawn up prior to sale of spirit in bond to Arthur Bell and Sons.

The Final Chapter

The final blow was loss of major export market, the US to Prohibition from 1920. The distillery ceased production in late 1924, and closed for good in 1926.

Maltings remained in use until 1970’s. Bonded warehouses were bought by Arthur Bell in 1931 and remained in use with United Distillers until 1989. The old bonded warehouses still exist to this day in Distillery Street, the warehouse doors still there, the laurel green colour inspired the Stratheden bottle label.

Until now.

Tasting Notes from the bottler:

Appearance: Full gold, with khaki lights. Thin but slow-running legs.

Nose: A dense, leathery nose with traces of dry fruit-cake, madeira cake and tinned pears, and a suspicion of scorched newspaper in the background. After a while a hint of pastry, hard toffee and sweet tobacco. A drop of water increases the pastry note, now buttery, and replaces the fruity notes with waxy green apple.

Palate: Sweet and peppery to taste, at bottled strength, with a trace of salt.

Finish: A warming, brilliantly long finish; oaky with a sugarcane essence. Lingering heat. Similar profile with water, at reduced levels, but without the salt and warm finish.

|

|

|

LOSSIT DISTILLERY

Lossit Distillery was located at Lossit Kennels, not far from Ballygrant on the minor road to Lossit Farm, close to Loch Ballygrant on Islay, as a medium-sized farm-scale operation. It was operated by Malcolm McNeill from 1817 to 1834, by the Stewart brothers until 1852 and a John Stuart thereafter for a further 10 years. This makes it one of the longest surviving 19th century farm-scale distilleries on Islay. There is a possibility that Bulloch, Lade & Co used the Lossit warehouses (perhaps to store Caol Ila whisky) until 1867. Today the house and kennels remain, although where whisky distilling actually took place remains a mystery and there is nothing left of the warehouses.

Lossit was the biggest producer of whisky on Islay in the industry’s formative years and lasted for half a century until it was silenced in 1867. The most successful of Islay’s farm-distilleries, Lossit was part of the transformation of Islay’s reputation from an outpost of smugglers to a leading force in the whisky industry.

The Early Days

Lossit featured all the amenities that made Islay distilling so desirable for illicit distillers: water, peat, space, and seclusion. As an illicit farm- distillery, Lossit relied on grain from its own supply of barley and fuel from the nearby peat bogs. Lossit would have changed little once licensed; most of the distilleries that emerged in the 1820s would have already existed prior to the 1823 Excise Act.

As a farm-distillery, Lossit was able to utilise its own available resources and ingredients for the spirit, using a work force that combined its duties as both distillery workers and farm hands. McNeill’s achievements as a distiller stemmed from his successes as a farmer. A successful harvest meant excess barley available for distillation; the end of the Napoleonic Wars had eased Britain’s grain crisis, meaning it could be used in products other than food.

Biggest Production Figures On Islay

Lossit’s production figures of 12,411 imperial gallons (56,421 litres) between 1823-26 at an average of 4,137 imperial gallons (18,807 litres) per year, the biggest on Islay, were achievable because of Lossit’s status as a high-quality farm. This was all the more remarkable considering Lossit’s illicit past, and the inherent weaknesses of the smuggling trade which many carried on into potstill legalised distilleries: a low yield of spirit, waste of spent grains and uneven quality of spirit were all hangovers of the illicit industry.

Despite these potential issues, McNeill managed to maintain the fragrant, characteristically peaty taste of Lossit that so many cherished.

Beginning of the End

Between 1835 and 1844, 61 distilleries in Scotland closed. Lossit was one of these. Malcolm McNeill, now beyond his middle age, began to settle outstanding debts to the ‘late distillery’ in 1842. His heir and son-in-law Charles McNeill showed more taste for farming than distilling, and the matter appeared to be settled when the resident gauger Alex Mathieson left in 1846. However, in 1849 an advert appeared in newspapers across Scotland, advertising an Islay distillery with a character ‘so long and so favourably established, that it requires no description.’

Lossit was not dead, but this was to be the end of its era as a farm distillery.

The distillery was purchased by the Stewart brothers, George and John Chiene, young men from Haddington, East Lothian, an agriculturally abundant area with a strong whisky heritage.

Aged 24 and 20 respectively in the 1851 census, the Stewarts took on Lossit solely as a distillery and removed the farm element.

The census labels George as the distiller and John Chiene as distillery manager; they are accompanied by a skeleton staff of three distillery labourers, all from Glasgow.

Opportunity Knocks

For the Stewarts, the opportunity to acquire a modern distillery with far superior transport links was arguably too good to miss. Lossit was limited, small and secluded in comparison, the qualities that made it perfect for illegal distilling now a hindrance. For Lossit, its spirit would continue to be used in the BLC blend and to furnish local markets, but any production had ceased by 1867. After Bulloch, Lade & Co relinquished its lease in 1870 and vacated the property, the distillery was gutted, and its plant buried in the property’s driveway. There the stills remain in their grave, the brand never to be tasted again.

Until now.

|

|

|

|

Archivist Vintage Archivist Select Classic with Tin

Tasting Notes: Lossit Archivist (46%, 2017):

Nose: Fruity sweetness, with a lot of punch, deep smoke and a salty hint. A little pineapple in the background, as well as something of buttered toast. Smoked fish. A creamier almond pudding note and a floral touch too.

Palate: Not very punchy, but good. Smoky bonfire, mint, citrus, liquorice and black pepper. Great structure and thickish feel. Also, the medicinal side comes out more.

Finish: Not too long, spicy and smoky.

Indeed this feels mature and balanced. The higher ABV makes it more flavoursome. Is this what Lossit tasted like? Cost around € 70.

The tasting notes of the Lossit Vintage feature in the video.

DALARUAN DISTILLERY

The Dalaruan Distillery (est. 1825) was located in the Campbeltown region, once home to 34 distilleries. Today, there are three. Dalaruan closed for good in 1925. Dalaruan was a triple-distilled single malt distillery and was a primary component of the Greenlees Bros. Lorne Blended Whisky.

Not many Scotch malt

whisky distilleries have a founding myth, although many wish they did. The

origins of a modern distillery are often born from conversations on a golf

course, in hotel bars or through numerous board meetings. Dalaruan Distillery,

once of Broad Street, Campbeltown, is said to have been conceived in bedroom

conversation. Its conceptual founder, Charles Colvill, once had to share a

hotel bed on Islay with a visiting excise officer who told him at length about

the whisky industry on the island. Charles gave up being an itinerant

Cartwright (cart maker) and turned to distilling, with considerable success.

The Early Days

Campbeltown’s first legal

distillery was built in 1817, imaginatively named Campbeltown Distillery.

Kinloch and Caledonian quickly followed, before the 1823 Excise Act finally

made legal distilling more viable by drastically reducing the cost of a license

and introducing modest duties for Highland distilleries. A flood of new distilleries

followed, encouraged by Crosshill Loch and the space to expand. Twelve

distilleries were built in the next five years, including Dalaruan (1824-25),

and a total of 29 were in operation by 1835.

A major part of the Campbeltown distillers’ success was their early investment in steamboats. The Campbeltown & Glasgow Steam Packet Joint Stock Co. was founded in 1826. For the next 111 years the company was to facilitate the carrying of cargo, passengers and mail to Glasgow, opening up the otherwise isolated Campbeltown to the wider world. In their centenary booklet, the company claims to have never lost a package or parcel, but they would say that! The steamers became synonymous with the town, their black and red funnels a famous sight on the Clyde. Merchants and mariners in Campbeltown had likewise long made use of the outstanding natural harbour, first for herring fishing and later to facilitate the whisky industry. Without the unique features of Campbeltown Loch, it is impossible the Campbeltown whisky industry could have developed to the level it did.

John Colvill, one of the

founders, was a wellknown and proficient maltster who kept meticulous accounts

of his transactions. These account books show that not only did John sell malt

to illicit distillers, but he also purchased their whisky subsequently for his

own personal consumption! Several of John’s account books record in striking

detail the process of building Dalaruan and its early business. The first entry

for Dalaruan distillery is on 5th February 1825, with construction lasting

approximately nine months. Dalaruan was part of an expansion of Campbeltown

northwards that also included the construction of Glenside, Kintyre, Dalintober

and Scotia (now Glen Scotia) distilleries, along with auxiliary buildings,

accommodation for workers and a series of colonial style mansions that stand

today in tribute to the great wealth a few in the town once attained.

A payment of £325 is the first recorded in the Dalaruan account book, receipted to Robert Armour. Armour

is an important figure in the history of Campbeltown distilling. A plumber by

trade, Armour also had an underground business building and maintaining

distilling equipment for use by individuals and groups to produce illicit

whisky. His expertise was an open secret, and within two years of the effective

legalisation of distilling Armour was tasked with the job of designing and

building Dalaruan’s distilling apparatus. The mash-tun, wash-backs, stills and

worm-tubs were designed and built by Armour, while ironwork and foundry

utensils were ordered from Mose McCulloch & Co, Glasgow. Flagstone was

imported from Arran, with shipments of a ‘bagg of hair’ (horse hair, for use as

a binder in plaster), slate and even bottles of ink recorded. Payments were

made to local craftsmen for the striking of a well, to carters for carrying in

pumps, to Nathaniel McNair for roofing the ‘still-house, fermenting tun-room,

spirit cellar and mill/kiln,’ and to James Johnston for painting the buildings.

Production started with a hydrometer, four hogsheads at a cost of 1 shilling, bolls of local bere barley,

liquid yeast coming from the Greenhead Brewery in Glasgow, who sent 16 gallons

of brewer’s yeast. Malting was performed on-site, with barley steeped in water

from Crosshill Loch before being spread across one of Dalaruan’s four

malt-barns.

Robert Armour installed the stills, the distillery was expanded and modernised several times and would have three pot-stills in the 1880s; a 2,750-gallon wash still, and two others with a capacity of 1,886 and 850 gallons respectively. Worm-tubs were situated outside of the Still House, parallel to a lade which ensured a steady stream of chilled water to condense the fresh distillate.

Testing of the equipment

and new make was to begin shortly after the purchase of a distillery licence

for £10 on 30th June 1825. 48 sample bottles arrived at Dalaruan in late

September, ready to be filled with new make spirit. David Colville, in

correspondence with Peter Reid (a merchant in Glasgow who acted as an agent for

Dalaruan) in early 1826, revealed that Dalaruan’s early product was gaining

weekly interest from Greenock, Glasgow and Leith. All three were key markets

for Campbeltown Malt, the name given to whisky from the area.

No expense had been spared

in the building of Dalaruan, a courtyard distillery designed for ease of access

by horse and cart. According to John Colvill’s account books, the distillery

cost a total of £1,778.10.4, with the brunt of the expense borne by himself and

Charles Colvill.

Dalaruan progressed

steadily, despite personal tragedy. A cholera outbreak in 1832 claimed the life

of John Colvill. In correspondence with David Colville, Peter Reid describes a

quarantine like environment and an understandable unwillingness to travel.

Ralph Langlands was the third founder of Dalaruan to die (Charles Colvill had

passed in 1828 aged 54) in 1839, and his share in the company was sold to John

McMurchy. The Colvill/Colvilles, along with the Greenlees family (to whom much of

their kin were inter-related), had become the premier distilling dynasty in

Campbeltown; their family was eventually linked to Dalaruan, Dalintober,

Argyll, Burnside, Kinloch and Springside, with the Greenlees linked to several

others, including Hazelburn.

Campbeltown Malt’s most

oft-cited description is by the writer George Malcolm Thomson under his

pseudonym Aeneas MacDonald. In Whisky (1930), MacDonald describes Campbeltown

Malt as: ‘The double basses of the whisky orchestra . . . potent, full-bodied

pungent whiskies, with a flavour that is not to the liking of everyone . . . so

masterful and assertive are they that the marrying of them to obtain a smooth,

evenly matched blend is an extremely difficult business.’

Richard Patterson, when

considering Campbeltown whisky many decades later, wrote that ‘these

characterful whiskies added genuine body and muscle, imparting almost an oily,

pungent influence to the blends.’ A general consensus emerged that labelled

Campbeltown whiskies as strong, pungent whiskies with a tang of salt and a tell-tale

peaty aroma. However, evidence showing the variety of still types used in

Campbeltown, and different distillation styles, makes such a judgement

premature. Dalaruan, in contrast, had been previously described somewhat grandiosely

as ‘hardly exceeded in the qualities of purity and strength, with an absence of

all disagreeable flavour or smell.’ It is a grandiose Victiorian statement, but

as Campbeltown Malt was known as a lighter, less peaty type than an Islay,

there may be some truth to it.

Dalaruan received its

mains water from Crosshill Loch, like other Campbeltown distilleries. The loch

was built by the Duke of Argyll explicitly to encourage the founding of

distilleries by offering a clean and consistent water supply. Crosshill Loch is

filled with spring water from further up Beinn Ghuilean, which flows over

limestone before settling in the loch. Limestone adds minerals like calcium and

filters out impurities. The area’s high volume of rainfall ensured the

distillers were never lacking for water. Dalaruan was supplemented by two

private 9-feet wells on its grounds which Alfred Barnard assured his readers in

1887 contained natural springs of the highest quality, principally for reducing

the alcoholic strength of the whisky before it was put into casks for

maturation.

Triple Distillation

When Barnard visited

Campbeltown in 1886, nine of the twenty-one distilleries working had three

stills installed; one for wash and the others for low wine and feints. These

would not produce the same style of whisky as those with two stills, nor of the

‘smuggling tradition.’ Dalaruan had long been an integral part of several

well-regarded blends, most notably the Greenlees Brothers’ Lorne Highland

Whisky & Old Parr. James Buchanan, founder of Victorian blending giants

‘Buchanan’s’, said that the Greenlees Brothers ‘practically held a monopoly’ on

the Scotch market in London. The Greenlees Brothers, Samuel and James, were

cousins of Dalaruan’s Managing Director Daniel Colville Greenlees (Son of

Daniel Greenlees and Grandson of Charles Colvill) and acted as agents for

Dalaruan in London, selling it alongside Hazelburn and Lagavulin. Hazelburn had

been founded by Dalaruan partner Daniel Greenlees, and they both shared three

stills as a defining feature. Dalintober, built by David Colville and Peter

Reid in 1832, used 3-stills.

The use of three stills

might just have been for convenience, but it is more likely that the distillers

at Dalaruan practised triple-distillation, along with other Campbeltown

distilleries. Dalaruan featured three pot-stills in the 1880s; a 2,750-gallon

wash still, and two others with a capacity of 1,886 and 850 gallons

respectively. Frustratingly little is mentioned about the practise, although

the distillation expert Joseph Alfred Nettleton describes triple-distillation

in relatively matter-of-fact terms, and the appeal of using full triple or

partial-triple distillation (like Springbank) to produce a lighter spirit is

understandable.

Triple-distillation would

increase the reflux during the total distillation regime, and reduce the amount

of less volatile constituents reaching the completed spirit. The technique

would ensure a lighter final spirit with a higher alcoholic strength than

normal double-distilled batch spirit. It is not dissimilar to the distilling

practise in Ireland, and the proximity and shared history of Kintyre and

Ireland could have encouraged a shared distilling legacy. The recycling of the

various fractions, and the deliberate extraction of strong feints from the

second still, would affect the bouquet and strength of the final spirit; a

higher alcohol content than the norm would be created, raising the number of

complex flavour congeners in the final spirit. Triple-distillation was

expensive and time-consuming, so its usage at Dalaruan was a choice of style

and flavour over efficiency. Worm-tubs were also situated outside of the Still

House, parallel to a lade which ensured a steady stream of chilled water to

condense the fresh distillate. This flow of cold water coupled with the frigid

Campbeltown climate would result in quicker condensation of the spirit within

the copper worm, helping to create a lighter-bodied whisky.

How long Dalaruan had been

practising triple distillation is unclear, but it is unlikely that Robert

Armour would have installed three stills during the initial building of the

distillery. Dalaruan was expanded and modernised at several points in its

history, and Alfred Barnard visited Dalaruan in 1887 after it had recently

constructed additional warehousing in

its three-acre site. Barnard was introduced to Dalaruan by Charles Colville Greenlees

in his office above the entrance archway, presumably with a welcoming dram!

Malting was performed

on-site, with barley steeped in water from Crosshill Loch before being spread

across one of Dalaruan’s four malt-barns. Distillers and brewers had begun to

use the Chevalier strain of barley in the late Victorian period, a two-rowed

strain of barley as opposed to the four-row Bere favoured earlier at Dalaruan.

Chevalier was more consistent and less volatile than Bere, resulting in mashes

less prone to spoiling. Chevalier needed to be imported, but the sheer demand

for barley from the Campbeltown distillers overwhelmed local producers; the

10,000 bags of barley that landed by steamer in 1869 for the distilling season

were the norm, not the exception. Chevalier was known for its relative

resistance to disease, and recent experiments with Chevalier indicate it added

malty notes when used.

Germinating barley was

then malted over peat fires in one of Dalaruan’s two capital kilns, each

approximately 33 feet in diameter and floored with Bridgewater tiles. Made of

clay, Bridgewater tiles were known for their xceptional heat conduction. Local

peat was available, but the supply was regularly superseded by shipments of

peat from the Hebrides and Ireland. John McKay, Campbeltown’s last peat cutter,

did not rate the Irish peat, which he described as turf! Moss peats were the

best in his opinion, for they could still dry in even the worst conditions.

These peats would contain less wood (measured in lignin levels) and more

sphagnum moss, adding a spicy, brackenesque element to the Dalaruan whisky.

The Equipment

The kilns would be at the centre of Dalaruan’s most dramatic episode, in July 1896 around 1am, a fire broke out in the Eastern kiln, and soon the adjoining stables were in flames. The fire spread to the granaries and malt barns and threatened to engulf the complex. Two watchmen on patrol sounded the alarm, but the fire would have been overwhelming had the lookout of a moored warship, the HMS Northampton, not noticed the blaze.

Over 50 Blue

Jackets (slang for British sailors) and their commanding officers were sent to

tackle the inferno. They ‘set to work with a will and vigour like only trained

men can’ and managed with some difficulty to put out the blaze. The granaries,

stores, lofts and kilns were gutted, but the major distilling equipment

survived – as did the whisky.

Barnard noted the seven

towering wash-backs as he made his way through Dalaruan. These wash-backs

contained wash that had been previously mashed in Dalaruan’s cast-iron,

two-thousand gallon mash-tun, and fermented using brewer’s yeast. In its early

years Dalaruan used brewer’s yeast from Greenhead Brewery in Glasgow, along

with casks of yeast sourced from Ayrshire of unknown heritage. Brewer’s yeast

is of the same species as baking yeast, but generally of a different strain.

Brewer’s yeast produces few off-flavours

and can tolerate higher alcohol concentrations, delivering more sulphuric

compounds to the wash depending on the original culture. Work within the

distillery could be highly dangerous. A worker at Dalaruan, Lachlan McLachlan,

was killed at the distillery in 1873 after his cravat was caught on a fan-shaft

and he was pulled inside the machinery, crushing him to death.

Hogsheads, puncheons, quarts

and octaves of Dalaruan would slumber in earthen-floored warehouses, draughty

buildings lined with black fungus. Light seeped through louvered windows

deliberately designed to encourage airflow. Located less than a mile from open

water, the damp atmosphere of the warehouses encouraged slower maturation,

resulting in smoother, saltier spirit than a drier, warmer environment would

have developed. Dalaruan was aged for as much as 27 years before being sold.

Casks of mature Dalaruan would be put onto carts to join the great procession

down to the quay, where men and their horses would wait patiently to load cargo

onto the steamers. This was a daily occurrence of Campbeltown life for over a

century.

Dalaruan in its early

years would have been filled into rum, sherry, beer, wine, fresh oak casks. It

was customary for clients to return their casks to the distillery, to be filled

again. Although it was not a legal requirement to age whisky until 1916, it was

understood that some aging was required to improve the youthful spirit. The use

of a rum cask by David Colville would impart hints of tropical fruit and

caramel notes.

Beginning Of The End

By 1835, there were 29

distilleries in Campbeltown, including Dalaruan – at its peak 34 distilleries

operated in the ‘whisky capital’ before economic collapse in the 1920’s.

Dalaruan Distillery was put up for auction and sold on April 8th 1925, along with 22,000 gallons of

matured whisky distilled at Dalaruan and Glengyle. A further 46,000 gallons of

stock, owned by customers, was available with the distillery, and the auction

had a total upset price of £15,000. The Dalaruan whisky inside these casks

would be of light body due to the use of triple-distillation, with heather and

smoke on the nose from the moss peat and malt from the Chevalier grain. The use

of rum and sherry casks would add flavours of tropical fruits and raisins,

while the unique Campbeltown climate would add a dry saltiness on the tongue –

a taste the town’s whisky is still known for.

Campbeltown’s demise in the

1920’s was down to overproduction, US prohibition, blenders preference for

Speyside Scotch, and the impact of minimum aging & post war tax increases –

this perfect storm forced distilling families to seek a better life abroad. On

Dalaruan’s closure in 1925, the buildings were demolished within five years and

replaced by a housing estate renamed Parliament Place. Parliament Place today

has the exact same boundary as Dalaruan, and a walk around the estate shows the

scale of the distillery, long forgotten. It’s a tragedy this legend was lost to

history.

|

|

|

|

GERSTON DISTILLERY

A Blended Malt produced by

The Lost Distilleries in homage to two of Halkirk’s lost distilleries.

|

| GERSTON 1 |

Gerston Profile: The whiskies used to create this blended malt were chosen for their assumed likeness to the character of two of Halkirk’s lost distilleries – Gerston I and Gerston II (later renamed Ben Morven).

One of the several brands

launched by the Lost Distillery Company since 2013, Gerston is an attempt to

replicate the spirit that might once have been produced at the two

distilleries, even though their styles may in fact have been quite different.

Nevertheless, Gerston blended malt is a sweet, fruity and smoky dram bottled in three expressions:

Classic, Archivist’s Selection and Vintage.

A Tale of Two Distilleries

The story of Gerston

whisky is a tale of two distilleries, known as Gerston One and Gerston Two.

Gerston One was a family-owned farmhouse scale distillery, with a typically

small output, making high quality spirit that was in demand both at home and

further afield. It was enjoyed by the great and good of London society and had

customers as far apart on the globe as Argentina, Brazil and India. It existed

for over eighty years, and remained in the Swanson family for nearly all that

time.

|

| GERSTON 2 - BEN MORVEN |

Gerston Two was an industrial scale distillery with a capacity of 80,000 gallons of spirit per year. The owners hoped to emulate the success of the whisky from Gerston One by building a new distillery, which had a capacity almost ten times the size of Gerston One. Production at Gerston Two lasted for little over two decades – they were unable to replicate the success and, importantly, quality of spirit previously associated with the Gerston name.

Gerston I was built by

Francis Swanson in 1795 on the family farm near the Thurso River at Halkirk.

The distillery represented one of the early success stories of the Scotch

whisky industry, its whisky was enjoyed far and wide, said to have been a

favourite of Prime Minister Robert Peel and the Duke of Wellington.

The distillery closed in

1875 and was demolished in 1882. Four years later a second distillery bearing

the Gerston name popped up, this time a more industrial, modern venture than

its farm-based predecessor. Though founded in 1886, it changed hands in 11

years to Northern Distillers Limited, who changed the name to Ben Morven. after

a nearby hill in 1897. Despite its state of the art set up – it was one of the

first to heat stills using steam from the boiler, rather than by a coal fire

underneath –and using the same water supply as the original distillery, Gerston

II/Ben Morven was a commercial failure. Ben Morven ceased to exist in 1900, and

was demolished in 1914.

The water source for

Gerston One was an unnamed stream next to Gerston farm. The water ran from a

nearby well before emptying into the Calder Burn. This would add a salty edge

to the spirit, neatly accompanying the strong peat reek of Gerston One whisky.

Gerston Two most likely used the nearby Calder Burn, which is a tributary of

the Thurso River. A separate channel was built outside the distillery, which

allowed water to flow through the complex for cooling and mashing.

Gerston One used local

peat from nearby Loch Calder. Peat cut in this area is distinctly briny and

salty. There is no evidence that Gerston Two used peat at all. When Alfred

Barnard visited in 1887, he noted that the spirit was “pure malt” a term, at

that time, used to describe non-peated whisky. Barley malted at Gerston One was

key to the success of the whisky. Evidence of this can be found from the 1826

Excise returns for Caithness, which noted that Gerston One produced 5763 proof

gallons from 2891 bushels of barley.

Gerston Two shipped barley

from the Lowlands of Scotland, and occasionally brought in barley from Eastern

Europe. They had malting floors covering 9000 square feet and were floored with

Portland concrete. Barnard noted the use of conveyors, and the saving of labour

in this part of the process.

The barley used at Gerston

Two could not attain the high yields attained by Swanson’s barley, and

subsequently the whisky was judged accordingly. Gerston One would have favoured

a combination of wild yeasts and domestic cultures. Wild yeasts are largely

air-born, and the domestic culture was derived from potatoes and sugar. Gerston

Two shipped commercial yeast supplied by Cameronbridge Distillery.

The Equipment

Gerston One would have

most likely used a puncheon or similar-sized vessel for mashing. As the process

was installed inside pre-existing farm buildings, they were always constrained

by height and space.

Gerston Two had a set of

four concrete mash tuns. Malted and kilned barley was elevated via a conveyor

belt and dropped straight into the concrete tun. The draff house was located

directly beneath the mash tun, and draff was collected via a sluice port.

Gerston One used a wooden

washback – again likely to be a puncheon in the earlier years then most

probably a purpose-built vessel as the business expanded. Gerston Two had six

wash- backs made of Quebec red pine. They had a capacity of 8000 gallons each

and were designed so they could be steam-cleaned after use.

The end for Gerston One.

Anecdotal evidence suggests that a neighbouring farmer dredged land adjacent to

the well, resulting in it drying up. A letter of 1975, sent to the People’s

Journal in Dundee claimed that the local water supply was ruined when a planned

extension to the distillery cut the flow of the spring, causing it to flow in

another direction. Either scenario would have been ruinous for the distillery.

At the age of 76, Swanson

quite possibly concluded that the business was no longer viable. The distillery

was sold but never produced the same quality whisky again and closed for good in

1875.

The end for Gerston Two

was traumatic. Gerston Two was built on an entirely different scale and was by

far the largest industrial complex in the area. When built it was the most

technically advanced distillery in Scotland. The Gerston Distillery Company set

out to develop the existing demand for whisky from Gerston One – particularly

in London. However, they chose industrial solutions to supply raw materials,

fundamentally changing the taste of Gerston whisky, and as a result found it

difficult to replicate the taste or quality of Swanson’s whisky.

The distillery was founded

in 1886, however in 11 years it changed hands to Northern Distillers Limited,

who changed the name to Ben Morven. Ben Morven ceased to exist in 1900, and was

demolished in 1914.

|

|

|

|

JERICHO DISTILLERY

Blended Malt Scotch Whisky: Jericho blended malt is

a recreation of the style of whisky thought to have been produced at the lost

Aberdeenshire distillery of the same name. Created by The Lost Distillery

Company using historical information since no liquid remains in existence, Jericho

is a sweet, Sherry cask-matured blended malt with notes of vanilla and spice.

The brand is now available in all three versions: Classic, Archivist and Vintage.

As Jericho is a trademark belonging to The

Coca-Cola Company, the brand is known as Benachie – a later name for the

distillery – in the US.

History

Jericho Distillery was founded in 1822 at the

remote farm of Nether Jericho in rural Aberdeenshire by William Smith, a deeply

religious farmer and the brother of a preacher from the nearby Parish of Oyne. The

farm was situated a few miles away from the town of Insch, where the distillery

set up its own shop, selling two-gallon ‘pigs’ of whisky.

Production started quickly, and by November 1824

‘Whisky from Jericho Distillery’ was advertised for sale in Aberdeen. ‘Jericho

Distillery Whisky from Jericho Distillery is to be had in Aberdeen only at the

shop of Will. Milne, 39 Broad Street.’

Jericho’s whisky was only really sold to the local

community, and although Insch received its own railway station in 1854, which

served Aberdeen and Keith, the distillery’s remoteness put it at a

disadvantage. It was renamed Benachie distillery after the nearby hill in the

1880s, but closed in 1915 during the First World War.

An attempt to reopen it came in the 1920s but ultimately failed.

In 1993 a range of Bennachie blended malts and a

blended Scotch named The Jock of Bennachie, were launched by the Bennachie

Scotch Whisky Company Ltd, a subsidiary of drinks group United Brands.

Bennachie was released as a 10-, 17- and 21-year-old ‘pure malt’, but withdrawn in 2014 with the dissolution of United Brands. The Lost Distillery Company released Jericho blended malt in the same year, launching Benachie (with one ‘n’) in the US.

Production

in the early years was on a modest scale. The extremely small stills and

rudimentary equipment was further evidence of the recent and short transition

from unlicensed to legal distiller. The small still whisky proved popular and

was sold throughout Aberdeenshire. Its reputation and fortunes progressed, and

the distillery was in good hands when Smith passed on the distillery to his

stepson, assistant and heir John Maitland in 1864.

Like others of its era, the distillery would have utilised a combination of wild

yeast and homemade cultures in the early years. Wild yeasts were air-borne and

notoriously unpredictable and did not tolerate low ambient temperatures.

Homemade cultures from potatoes and sugar were prone to creating off notes and

were frequently full of bacteria and other contaminants. Dried yeast offered

far greater reliability than wild yeast and allowed the newly modernised

Benachie to produce wash of consistent gravity. The distillery was one of the

first to adopt sherry casks for maturation. The quality and flavour of whisky

was significantly improved as a result.

Peat was readily available in the Aberdeenshire area where Jericho resided; indeed,

it was noted as a selling point of the distillery when it was put up for sale

in 1883. Derived from decomposed moss, shrub, leaf mush and heather, the peat

would have added an earthy, woody note to the whisky. Used extensively by farm

distilleries like Jericho in the distillation process, including to fire the

stills, peat was still utilised by the modernised Benachie as the sole fuel to

dry the barley, leaving an indelible mark on the character of the spirit.

The Equipment

The distillery’s original

mash tun was a small, handturned wooden vessel. Operating this primitive

apparatus was a tiresome task, and the resulting mash was frequently lumpy with

sugars poorly extracted. When John Maitland instigated his renovation and

modernisation of Jericho in the late 1860s, an easily- cleanable iron tun was

installed, measuring twelve feet in diameter and four feet in depth. The new

tun had a mill-driven mechanical arm with revolving stirring gear attached. The

rakes turned the mash, an automated process that offered better extraction of

sugars and more consistent wort. In 1830, the distillery had six wooden

washbacks, each averaging 880 gallons. These would have been difficult to keep

clean, particularly after fermentation using yeast cultures that were

potentially contaminated. Yeast activity was largely temperature driven, which

meant that fermentation times in the washbacks could vary, and the strength of

the wash was never consistent. Jericho probably aimed to run off a wash six

days per week, although in earlier years at least, the volatility of primitive

yeasts ensured that completing all six was never guaranteed. There were four

washbacks in the Benachie era, each with the capacity of 3000 gallons.

Therefore the volume of wash at the distillery was more than doubled:

Jericho: 6 × 880 = 5,280 gallons wash capacity

Benachie: 4 × 3000 = 12,000 gallons wash capacity

Both Jericho and, in later years, Benachie specialised in small still whisky

distillation, a continuation of techniques originating from the unlicensed

pre-1823 era. A comparison of still capacity shows the progression made by the

distillery:

1830 Jericho: Wash Still 244 gallons Spirit Still 67.5 gallons – these stills would

have produced an extremely heavy and oily spirit.

When the still house was redesigned in the early 1880’s, Callander and Graham installed new stills:

1884 Benachie: Wash Still 1400 gallons Spirit Still 706 gallons

Therefore, wash still capacity was increased fivefold, and spirit still capacity tenfold.

The new spirit still of 1884 was characteristically squat in shape but with a

taller neck, meaning the Benachie spirit would have been slightly lighter than

that of Jericho.

The Final Chapter: 2014

As the Second World War dawned, a dance was held to celebrate a wedding in the old malt barns of Benachie. An old cask of Benachie was pulled out, probably the last in existence. The wedding guests danced the night away, emptying the cask in the process. It was assumed that they would be the last people to taste the delicious, sherry-matured whisky that made first Jericho then later Benachie so famous.

|

|

|

Tasting Notes: Jerich Archivist

Colour: A deep, dull amber, moody and dark. The liquid puts a nice coat on the glass,

which unfolds its legs more than drops them.

Nose: Rich, with dried fruits, tangerine and marzipan. There's also a hint of molasses

and leather that goes very well with the slight smoke, typical of these types

of whiskies in those days.

Palate: Spicy but fresh, with cinnamon and black pepper. The fruitiness of the nose

keeps on going with sherried notes and even darker fruits.

Finish: Medium, dry and oily. Rich in sweet spices.

The Bennachie?

The Bennachie (note the double n) was revived as an independent bottling label in 1998 with the full line of releases hitting the market in 2000. United Brands of La Mesa, California oversaw the brand during the early years of the 21st century.

The Bennachie label was established as an independent bottling of what the company describes as a “pure malt.” The more common terms regarding similar Scotch releases would be blended malt. The now discontinued “pure malt” lineup originally included 10-year-old, 17-year-old, and 21-year-old releases each housed in a distinctive squared bottle reminiscent of those used by Elmer T. Lee and Old Medley bourbons.

Tasting Notes: Bennachie 21 Year Old 40% ABV

Appearance: Light golden honey with greenish tones. Quick, thin legs.

Nose: Vanilla cream. Oak, more green than charred. Unidentifiable yet vaguely familiar chemical smell in the mix. Mint on the tail end of the nose.

Palate: Very delicate. Light on flavour with a very light burn. Sweet cream. Vanilla. Clean and straightforward.

Finish: Very quick and light. Almost nonexistent. Aftertaste of cream soda.

Beyond a display piece, Bennachie 21-year-old falls completely flat as an example of the Speyside region or a malt blend.

|

|

|

THE LOST DISTILLERIES OF ISLAY

Whisky history has seen periodic fluctuations of demand negated by downturns when distilleries have had no options but to close. Islay has lived through the ups and downs and has gone from a high of 23 distilleries to a low of 6 to the current status of 9. And more are coming! But many lost distilleries live on through tales, legends, names and edifices that now lie in ruins or have found other uses. Despite its small size, Islay has been home to many distilleries over the years, several short lived whose history lingers on in memorabilia, stories, ruins or names.

ARDENISTLE DISTILLERY

Laphroaig had been established by Alexander and Donald Johnstone in 1815, but just decades after its construction its reputation attracted the attention of two Scots financiers, James and Andrew Gardiner. In 1837 the duo bought some land adjacent to Laphroaig, built their own distillery and recruited two Stein brothers, also James and Andrew, to run it, all in the hope of emulating Laphroaig’s success. They may have been the first to attempt to replicate Laphroaig, but they certainly weren’t the last.

The distillery, which was originally named Ardenistle, ruffled a few feathers next door. Donald Johnson, the owner of Laphroaig, was deeply disturbed finding out that the new Ardenstiel Distillery proposed to use the same water source, water that had made a vital contribution to Laphroaig’s unique character and at a time when he was about to expand his business and had been left with a too small water supply.

The Steins found themselves in a protracted argument with Donald Johnston over water rights (ironically, water continued to be a source of contention between the owners of Laphroaig and Lagavulin in the early 19th century, with the latter blocking the former’s access entirely).

James and Andrew Stein took charge of the distillery around 1840 and distilled until 1846. The dispute lasted through those six years and ended abruptly when Andrew Stein fill ill with fever and died soon afterwards. His brother Jmaes stopped distilling and moved to Port Ellen where he managed the Port Ellon Distillery for John Ramsay. Donald Johnston tragically also passed the following year after falling into a vat of boiling pot ale.

After a silent period, James Morrison took on the licence in 1849 and changed the distillery’s name to Kildalton, though it closed again after three years. The distillery then passed through several hands, including Hunter & Sharp (who renamed it Islay distillery), John Cassels and ultimately, William Hunter. He struggled to make it pay, operating at half capacity producing 33,000 gallons per year. By February 1866, William Hunter went bankrupt and pulled down its shutters.

Ardenistiel was incorporated into Laphroaig when it failed, largely due to the neglect of the manager who was more interested in using the kilns to produce smoked ham. He installed 2000 pigs to graze on Texa islet just offshore from the distillery but that venture, too, failed and he went banktupt.

Ardenisteil’s derelict buildings eventually became the site of Laphroaig’s warehouses and offices while those parts of the distillery not incorporated into Laphroaig were finally demolished in 1868.

ARDMORE DISTILLERY

Nestled on the south of Islay, Scotland's Whisky island, two distilleries were located in its small and beautiful bay, within view of the Dunyvaig Castle ruins. Records show illicit distillation in at least ten illegal distilleries on the site as far back as 1742. The distillery's water source, Lochan Sholum, is situated 200m above sea level, and the water flows down the hillside through the peat - this water helps give the whisky its distinctive taste. The distillery of Lagavulin officially dates from 1816, when John Johnston and Archibald Campbell Brooks constructed those two distilleries on the site. One of them became Lagavulin, the other Ardmore, or Lagavulin 2. Ardmore opened as a 92-gallon, single wash distillery, but within a year was operating under double distillation with the addition of a 30-gallon low wines still. Both distilleries took advantage of its coastal location, allowing the sea air to work on the spirit as it rested in the barrels.

Lagavulin distillery is located on the south shore of Islay at Port Ellen and is a direct neighbour to the Ardbeg and Laphroaig distilleries. As a distillery, Ardmore didn’t see much success and in 1825, Johnston took it over and ran both neighbours for a decade simultaneously, often using the names Lagavulin 1 and Lagavulin 2. Johnston died in 1836 and in 1837 a valuation carried out shows the two distilleries as having operated during John Johnston’s tenancy. The Still House (No 2), Tun Room and Malt Barn No 4 were all listed as belongings to the Laird Walter Frederick Campbell, as Ardmore Distillery.

Alexander Graham, a Glasgow distiller-merchant and owner of Islay Cellar that supplied Islay Malts in Glasgow and to whom Johnston was indebted claimed first right to Lagavulin and took over in 1836, installing his son Walter Graham as the distiller. In 1845, Walter Graham initiated the merger of Ardmore with his own, aiming to leave only the first and original Lagavulin running on the site, but with an increased capacity. He moved to Laphroaig in 1848, and the merge was completed by 1852. It was only in 1887, when Peter Mackie took the helm, that the distillery and the Lagavulin name ascended to be the quintessence of Islay malts.

MALT MILL DISTILLERY

Micro-distillery built at Lagavulin with one of the most enigmatic tales in Scotch whisky history. Malt Mill produced a peated whisky that contributed to some of Mackie & Co., and White Horse Distillers’ blends, including White Horse and Mackie’s Ancient Scotch.

Malt Mill was born in 1908 from an acrimonious falling out between the owners of Lagavulin and Laphroaig. From 1908 to 1962 on the site of the current Lagavulin visitor centre, a distillery called Malt Mill was opened by Peter Mackie in attempt to recreate the style of neighbouring Laphroaig distillery. The distillery was integrated into Lagavulin in 1962 effectively ceasing to exist.

A Distillery Within A Distillery

A number of distilleries have existed within a single complex before such as:

- The Inverleven Stills at Dumbarton Grain distillery

- Glen Flagler & Killyloch within Garnheath Grain distillery

- Ben Wyvis within Invergordon Grain distillery

- Ailsa Bay within Girvan Grain distillery

Malt Mill Becomes Famous

The lost Malt Mill distillery was catapulted to fame by the film The Angels’ Share, although filming actually took place at Balblair, Glengoyne & Deanston distilleries rather than Lagavulin. The film, which takes its name from the romantic name given to whisky lost to evaporation, centres around the discovery of a mythical last cask of Malt Mill headed for auction.

In a surprising twist, while no last cask exists a final bottle did surface as a consequence of the film. Then Lagavulin distillery manager Georgie Crawford heard about the Cannes award winning film then fetched the only existing bottle, which was passed on to her by her predecessor. It’s now on display at the Lagavulin distillery for visitors to see. In 2018 one of the only bottles of whisky bottled by the enigmatic lost distillery went to auction fetching £3,400. The miniature is thought to have sourced by independent bottler James MacArthur & Co. and one of four obtained by a collector in the mid-1990s.

‘Restless Peter’ & White Horse Distillers

In 1880 James Logan Mackie founded whisky merchant James Logan Mackie & Co. which held part ownership of Lagavulin. In 1879 he was joined by his nephew Peter Mackie who trained at Lagavulin. A year later James Logan Mackie & Co changed its name to Mackie & Co. and launched the White Horse blend. The same year Mackie & Co. acquired a stake in the newly built Craigellachie-Glenlivet distillery and acquired Greenlees & Colville Ltd, which owned the Campbeltown based Hazelburn distillery. By 1921 Mackie & Co. had taken control of Craigellachie-Glenlivet and secured half-ownership of Cragganmore in 1921. At the time of Peter Mackie’s death in In 1924 the firm was renamed White Horse Distillers in recognition of the brand which had become one of the best-known in the world.

Beyond his own distilleries, Mackie was heavily involved in the Scotch whisky definition debate between 1905 and 1909 and a campaigner for a minimum maturation age, which was finally realised in 1915 with the introduction of the Immature Spirits Act. For these efforts Peter Mackie was somewhat deservedly nicknamed Restless Peter. While his boundless energy and grand vision is obvious it would also be fair to say that he was in possession of a dangerously short fuse. In addition to his response to the ‘People’s Budget’ of April 1909 shown below, his temper also resulted in the creation of Malt Mill distillery.

“The whole framing of the Budget is that of a faddist and a crank and not a statesman. But what can one expect of a Welsh country solicitor being placed, without any commercial training, as Chancellor of the Exchequer in a large country like this?”

The Laphroaig Row

For around 80 years the Mackies had acted as sales agents for Laphroaig as a brand, while also using large quantities of the distilleries output in their own White Horse blend. The death of Laphroaig owner Alex Johnston in 1907 brought his nephew, Ian Hunter, to the island. Hunter, a newly qualified engineer, was disappointed by the state of the agency agreement. He felt Laphroaig was not getting the best returns since Mackie was demanding most of the distillery’s output for its own blends. What ensued was a bitter court case, in which Mackie lost the right to represent Laphroaig.

When Laphroaig ended their contract with Mackie as agent, his first act was to block the water supply of Laphroaig. It took a court case to make him restore the waterway. In response he created a replica of Laphroaig distillery, and convinced Laphroaig’s master distiller to leave the company and run it to ensure the spirit produced was exactly the same as his neighbour’s. The distillery was known as Malt Mill. Of course the spirit produced wasn’t Laphroaig. It wasn’t Lagavulin either.

Ultimately it seems his attempt failed as the spirit was distinctly different from that produced by Laphroaig, but inspite of this the Malt Mill distillery continued until 1960. Malt Mill’s peated whisky spirit was a contributor to some of the blends produced by Mackie & Co. & White Horse Distillers, including White Horse and Mackie’s Ancient Scotch. While the former blend is still in production today, the latter was a comparatively rare blend from the 1930s and 1940s. Both featured the name of the distillery on the label. It was never – as far as historians know – bottled as a single malt.

Malt Mill Timeline:

1908: Built by Mackie & Co. (Distillers) Ltd. after they lost the agency for Laphroaig in 1907

1927: The distillery along with Lagavulin becomes part of DCL (Distillers Company Ltd.)

1960: Closed about 1960

1962: Malt Mill is closed entirely and incorporated into Lagavulin

1974: The old maltings are closed and refurbished as a visitor centre

2012: Malt Mill is popularised after a cask of its whisky appears in the The Angels' Share and Donnie MacKinnon former head brewer unveils the last remaining bottle of Malt Mill that he filled fifty years ago

2018: A 5cl miniature of Malt Mill went on auction for £3,400

The videos serve as great tasting notes.

ReplyDelete